Recently, I have received many inquiries from friends in the background, all about the production of acrylic signs. The first sentence at the beginning is often "How much does it cost to make an acrylic sign?" ”Or as mentioned in the title, it is directly "production inquiry". To be honest, every time I see such a question, I find it a bit difficult to deal with. It's not that I don't want to quote, but it's just that it's really impossible to say in one sentence, just like when you go to a restaurant and ask "How much does a meal cost?" ”, people also need to know what you want to eat, how many dishes you want to order, and whether you want to drink, right?

So, let’s talk today. Before you go to the manufacturer to make an inquiry (for example, the “cz66zh” you mentioned, I guess it may be a contact code or the manufacturer’s abbreviation), it’s best to figure out what you need to know first. Once you understand these things, you can ask for a price, and the other party can give you a reliable quotation. You can also compare which one is more realistic, not easy to be fooled, and the final product is more in line with expectations.

.jpg)

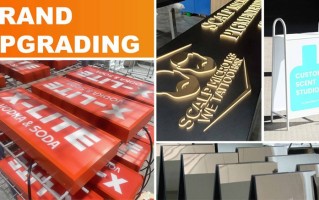

First, you have to know what you want. This sounds like nonsense, but many people really don’t think carefully about acrylic signs. The thickness of the material alone is 3mm, 5mm, 8mm, or even thicker. ; The colors include transparent, milky white, colorful, and those with a metallic effect. ; In terms of technology, there are silk screen printing, UV printing, engraving, back lamination, hot bending... there are so many tricks. Do you want a simple double-sided silk screen door plate, or a brand logo with a three-dimensional luminous effect? Is it for indoor use or for outdoor use where it will be exposed to the sun and rain? Is it the size of a palm, or the size of an entire wall? Even if you only have preliminary ideas about these things, it is best to sort them out. Even if you draw a sketch or take a reference picture, it is a hundred times better than simply saying "I want to make an acrylic brand."

Secondly, quantity is a key factor. This is definitely a big factor that affects the unit price. If you only make one piece, or if you make a hundred, the unit price can differ several times. If you only make one piece, the fixed costs of startup fee, plate making fee, and mold fee (if necessary) are all shared on this piece, which will definitely be expensive. If it is mass production, these costs will be evenly shared, and the unit price will naturally come down. Therefore, when making an inquiry, be sure to clarify whether it is proofing or mass production, and the approximate quantity. Many manufacturers (including the manufacturer behind the code you mentioned) have completely different quotation systems for small orders and batch orders. Don't expect to use the price of one piece to measure the unit price of 100 yuan. This is unfair and unrealistic.

.jpg)

The third point is, don’t just look at the price number, ask clearly “what is included”. Some quotations may seem low, but they may just be bare-brand prices, excluding design fees, transportation fees, taxes, and even standard surface protection films. After you place an order, the total cost may be more expensive than a manufacturer with a slightly higher quotation but "all-inclusive". For formal inquiries, you should try to ask the manufacturer to provide a detailed quotation that includes material specifications, process details, quantity, unit price, total price, delivery cycle, payment method, packaging and transportation methods. Vague quotations often have pitfalls hidden behind them.

The fourth point, cz66zh" or any manufacturer code. I understand that this may be an internal contact code or the abbreviation of a certain manufacturer. When looking for suppliers online, it is best to be more careful when encountering such codes. Try to use it to find the manufacturer's more formal company name, check its official website or case works, and directly use a code to inquire. If the other party is a regular salesperson, it may be understood, but the communication may not be smooth. More importantly, Be sure to look at actual cases or proofs! Acrylic may have differences in texture, thickness, purity of color, cutting and edge sealing process, and the actual product. Especially if you have quality requirements, you may want to ask the intended manufacturer to send a small sample (usually for a fee) to see the actual material and workmanship level. This is more useful than comparing ten low prices.

A few final words, the acrylic sign production industry is very mature, and the prices are actually quite transparent. The difference in quotation lies in the material itself (whether it is using new materials or recycled materials), process accuracy, and the manufacturer's service and quality control. Don't blindly pursue the lowest price, which may mean compromising at some point. It will be much more comfortable to cooperate with a manufacturer who has smooth communication, can help you clarify your needs, and is willing to provide detailed plans and quotations.

Next time when you are preparing to make an inquiry, you might as well stop and sort out the demand, quantity, and general requirements, and ask with this information. What you will get will no longer be a cold number, but a valuable solution reference. You will know how to spend the money. After all, what we want is not the cheapest, but the most suitable and worry-free, right?