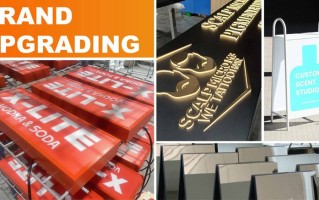

Recently, while sorting out the background messages and discussions in industry groups, I discovered a very interesting phenomenon.: Many customers, whether they are companies making signs for the first time or veterans who need iterative upgrades, have gone through some detours when looking for stainless steel sign metal parts processing manufacturers. Some people are trying to get a cheaper price, but the products they get are rusty and have cuts on the edges within a few months. ; Some people blindly pursue "big brands", not to mention high communication costs and delayed delivery times, which delays things. Let's put aside those flashy advertising slogans and talk about what to look for when choosing a reliable stainless steel sign processing manufacturer. What are the doorways and pitfalls that are easy to step on?

.jpg)

Let's be clear: Stainless steel signage is not just a piece of iron with printed words on it. It is the outpost of the corporate image and the core of environmental guidance. It often also carries the function of safety instructions. Its quality, craftsmanship details and durability are directly related to the user experience and long-term value. A reliable manufacturer can not only "make it", but can "do it well", and can understand "why you need it so well".

How to judge whether the manufacturer is reliable? I think we can pay more attention to the following aspects.

First, value "lizi" rather than "face." Many manufacturers have high-end websites with bright and beautiful case pictures, but don’t be fooled in a hurry. You might as well ask in depth which stainless steel raw material they use? Are they genuine materials from major manufacturers such as Taiyuan Steel and Baosteel, or recycled materials or inferior materials from unknown sources? Is the thickness of the board sufficient (for example, it is said to be 1.2mm, but it is actually only 1.0mm or even thinner)? Is the material 304, 316 or 201? This price difference is far different from the corrosion resistance. An honest manufacturer will be happy to explain the difference in materials to you and give professional advice based on your use environment (such as indoors, outdoors, coastal high-saline-alkali areas), rather than blindly recommending the most expensive or cheapest.

.jpg)

Second, the details of the craftsmanship can be seen in the real chapter. The texture of stainless steel signs is largely determined by the processing technology. Is laser, water jet or plasma used for cutting? Laser cutting has high precision and smooth cross-section without burrs. This is the basic requirement. Is the arc at the bend rounded and even? Are the welding points ground flat and polished so that they feel almost "seamless"? Especially the surface treatment, is it simple brushing and mirror polishing, or does it need etching, embossing, sandblasting, titanium plating (color)? A good manufacturer will have a wealth of process samples for you to actually touch and feel, and can clearly explain the advantages, disadvantages and applicable scenarios of each process. You can pay special attention to the corner treatment of the sign. Good processing will definitely carry out fine chamfering or curling to prevent sharp edges from scratching people. This detail is ignored by many small factories.

Third, don’t underestimate your design and communication skills. Do you think the processing plant only builds according to the drawings? In fact, this is not the case. An excellent processing manufacturer often has certain design optimization capabilities. The drawings you give may be just concepts. Based on actual processing experience, they can tell you which structure is more reasonable, more material-saving, and more stable, which lines are easily deformed in actual production, and how to adjust them better. Whether the communication is smooth and whether the response is timely is also very important. From inquiry, confirmation of drawings, process discussion to production progress tracking, a responsible docking person can make the whole process half worry-free. The most fearful thing is that if you ask three questions and reply with one answer, or agree to everything, it will not be the case at all.

Fourth, conduct field visits or look at “real” cases. If the order is important and conditions permit, it is really recommended to go to the factory and see if it is clean and orderly? Is the equipment up-to-date and well-maintained? Are the workers' operations standardized? These can directly reflect the factory's management level and quality stability. If you can't go, be sure to ask them to provide the most recent, directly shot (not stolen pictures) actual case videos or high-definition detailed pictures, especially those with complex craftsmanship.

Speaking of "pits", the most common ones are just these: low price trap (Use inferior materials and simplify processes) ; Construction period deception (Promise to be fast in the early stage, but delay for various reasons in the later stage) ; Responsibility wrangling (When problems arise, they blame them on design drawings or transportation problems) ; Cutting corners (The places that should be thick are thin, and the places that should be polished are polished twice.) There is no shortcut to avoid these pits. Just spend more time in the early stage to investigate, compare, and ask questions.

Choosing a stainless steel sign metal parts processing manufacturer is a bit like finding a partner. It requires solid technology, sincere attitude, and transparent communication. Price is certainly an important factor, but it is by no means the only factor. You get what you pay for, which is still the last word in the field of industrial manufacturing. I hope you will do it next time When you need to make stainless steel signs again, you can filter with a clearer idea and find the "treasure" manufacturer that can really help you put your ideas into practice and make quality products. After all, a good sign can be used for many years, and it is worth the extra thought you spent in the early stage.