Recently, many friends in the background have been asking about the price of metal wine labels, especially those marked with "manufacturer direct sales." To be honest, this industry is quite deep, and it is not something that can be explained clearly by simply reporting a number. Today we will break it down and talk about the twists and turns behind the price of factory direct sales.

Let me first talk about a real case I encountered last week. A friend who makes craft beer wanted to customize a batch of brass wine labels. The quantity was not large, just 500. He asked for prices on Taobao, 1688, and several so-called "source manufacturer" websites at the same time. The prices quoted ranged from 3.5 yuan to 18 yuan each. He was completely confused. The cheapest one had a very detailed page. , the picture is also beautiful, but if you look closely, the material is written as "brass-colored alloy". To put it bluntly, it is copper-plated zinc alloy, the thickness is only 0.8mm, and the corners are rough. The most expensive one uses real H62 brass, with a thickness of 1.5mm, all edges are polished and chamfered, and even the solder joints on the back are cleanly processed. This price difference does not come out of thin air.

So you see, the first clue to the factory direct sales price lies in the two words "material". It is also "stainless steel", and the cost difference between 201, 304 and 316 can be more than double. Some manufacturers say it is 304, but actually mix it with 201. Ordinary consumers simply use it. I can't tell it at all. It would be weird if it doesn't rust after one or two years of use. Brass is also divided into copper, brass, and bronze, and there are various markings, not to mention those "antique and distressed" effects. The texture of real corrosion, hand polishing, and spray paint are completely different. The price is naturally very different.

.jpg)

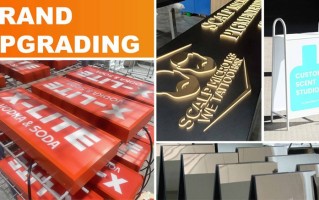

The second key point is craftsmanship. Don’t underestimate a brand. From blanking, cutting, stamping, and bending to welding, polishing, electroplating, silk screen printing, or corrosion filling, there are so many processes. For surface treatment alone, there are mirror polishing, brushing, sandblasting, titanium gold plating, rose gold plating, antique plating, enamel color, etc. In order to keep prices down, some small factories will omit the intermediate polishing or degreasing steps and directly apply color. At that time, I saw It is very bright, but the adhesion is not good at all. It fades after being touched a few times. The complex three-dimensional relief effect and simple plane corrosion mean that the processing time and scrap rate are not at the same level. The most exaggerated one I have ever seen is a red wine winery badge sign with extremely fine grape vine relief. It has to be slowly pressed out with a precision mold. The mold opening cost alone is tens of thousands. If it is spread to each brand, can the cost be low?

Let’s talk about “minimum order quantity”. This is the core secret of factory direct sales price. You ask, “How much does one cost?” ”The manufacturer has no answer at all. For real manufacturers, the cost is high when the production line is opened. What they like most is a large order that can "run the volume". If they make 500 pieces or 5,000 pieces, the unit price may differ by more than 30%. Because of mass production, the plate utilization rate is high, the mold loss is diluted, and the workers are skilled. The level of proficiency has also improved, the efficiency is high, and the scrap rate is low. Those who claim "one piece minimum order" and quote ultra-low prices are 80% middlemen or small workshops. They may take standard parts from large factories and reprocess them, or use scraps from inventory. If you really believe it, delivery time and quality are not guaranteed.

Design complexity is also an invisible killer. If you give a ready-made vector drawing, or if you just give a vague logo concept and let the manufacturer redesign it, the quotation will definitely be different. The lines are too thin and easy to break, and the color blocks are too large and the plating is uneven. Experienced manufacturers will tell you in advance about these design pitfalls and help you adjust the plan. This service is also cost-effective. For those who are inexperienced or want to save trouble, they will just follow your example. The result will not be good, and the wrangling will be more troublesome.

.jpg)

There is another point that is easily overlooked: For surface protection, wine labels often come into contact with ice water, alcohol, and the environment is humid, so the final layer of transparent protective paint or sealing film is particularly important. A good anti-oxidation treatment can keep the bronze medal from discoloring for ten years. The worse one, it will turn black in a few months. The materials and labor hours of this layer of craftsmanship are also reflected in the price.

So, back to the original question: How much is the price for metal wine signs to be sold directly from the manufacturer? I can tell you now that it is not a fixed number at all. It is like a sponge, which is filled with "moisture" such as material, process, quantity, design, and post-processing. If the price is too low, the manufacturer can only squeeze out the "moisture" from these places. What you end up with may be a shrunken "sponge".

So how should I ask for a reliable price? My suggestion is, don’t ask “how much” at the beginning, clarify your needs first: What material is required (it is best to tell the specific number), approximate size and thickness, what kind of craftsmanship is required (such as brushed surface or mirror surface), required quantity, whether there are ready-made design files, and how long it takes to expect delivery. Only by packaging this information to the manufacturer can the quotes obtained be comparable. After getting the quote, be sure to ask the other party to send a physical "proof". Even if you pay a little for proofing, it is worth it. The feel, color, and details can be known at a glance.

One last word, when buying this kind of product, especially for high-end wines, you really can’t just look at the price. A metal sign with excellent texture is the “face” of the wine and can instantly enhance the quality of the product. In order to save a few dollars, the entire product is messed up. When looking for a manufacturer, in addition to looking at the price, you also have to look at the cases they have done, talk to their business or technology, and feel their professionalism and sense of responsibility. Spend a little more and buy a worry-free and long-lasting product.

After all, there is nothing unreasonably expensive in the market, and there is nothing unreasonably cheap. If you look over the price tags sold directly by manufacturers, the word "value" is written all over it. I hope this article can help you feel more confident next time you inquire.