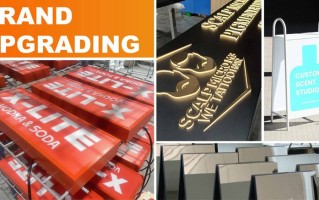

Recently I have received a lot of private messages in the background, and the most frequently asked questions are:: “Editor, our company wants to make a batch of metal signs. What kind of manufacturer should we look for? ”To be honest, this issue cannot be explained clearly in one or two sentences. There are so many manufacturers of metal signage on the market. From small street workshops to large-scale manufacturers, the price, craftsmanship, and service vary greatly. Today, I will use my experience of visiting factories and looking at cases in the past few years to talk to you about the secrets behind this.

First figure out what you want

Don't rush to find a manufacturer. The first step is to understand your own needs. Do you want to make the kind of atmospheric three-dimensional stainless steel characters at the entrance of your company? Or the delicate brass signage in the mall? Or do you need a corrosion-resistant aluminum nameplate on your equipment? Different materials, processes, and quantities directly determine what type of supplier to find.

I have seen many customers who initially only asked "How much does it cost to make a metal sign?" However, the manufacturer quoted a price, but the result was not what they wanted at all. The same stainless steel letters, ordinary laser cutting and precision mirror polishing, the cost can be several times different. If you want to make luminous letters for high-end stores, but you find a small factory that mainly makes mechanical nameplates, the effect will definitely be greatly reduced.

.jpg)

Manufacturer type starts from the bottom: Everyone has their own way of living

According to my observation, manufacturers on the market can be roughly divided into the following categories::

Large comprehensive signage company This type of company is large in scale and has complete workshops. From design, sheet metal, welding, polishing to painting and installation, it can often be handled in one stop. The advantage is that the process is comprehensive and it can handle large and complex projects, such as the signage system of the entire building. However, the disadvantage is that if your quantity is relatively small or the process is particularly simple, they may not be too interested and the quotation will be relatively high. The communication process is sometimes more "formalized" and not so flexible.

Specialized craftsman This is the category I like to deal with the most. They may not be the largest in scale, but they are often particularly good in a certain niche. For example, there are manufacturers that specialize in the mirror or brushed effects of stainless steel, and the work they do is beautiful. ; Some are good at making heavy cast copper signs, with a retro texture that no one can match. ; Others focus on precision etching and can carve complex patterns on thin aluminum plates. If you ask them to do a specific process, the cost performance and finished product effect are usually surprising, but the premise is that you have to clearly know what process you value most.

localization service provider There are several local sign companies in almost every city. Their advantages are fast response, easy communication, and timely installation and maintenance. They are suitable for projects that require local installation and subsequent maintenance, such as signs for chain stores. Their processing capabilities may be limited, complex processes may require outsourcing, and quality stability requires careful examination of past cases.

Source material/semi-finished product supplier Strictly speaking, these types of companies are not "sign manufacturers", but they are very important, such as material suppliers that specialize in aluminum profiles, stainless steel plates, copper plates of specific thickness, or semi-finished product processors that specialize in standardized metal letter shells and base plates. Many small and medium-sized sign companies actually get materials or semi-finished products from them, and then carry out deep processing and assembly. If you have a large order, or want to control the core materials yourself, you can save a lot of money by going to them directly, but only if you know the industry yourself or have a reliable processing partner.

.jpg)

How to find it? Don’t just rely on Baidu

Now that you know the type, where can you find it? A few years ago, everyone might just search on Baidu, but now, I think these methods are more reliable.:

Recommended by peers: This is one of the most reliable ways. Ask your friends who have done similar projects, what pitfalls have they encountered, and which manufacturer are they satisfied with? Real cooperation experience is more effective than any advertisement.

Vertical industry websites or exhibitions: For example, some industry websites such as advertising signs and commercial displays have relatively professional manufacturers. If you have the opportunity, go to relevant industry exhibitions and you can directly see physical samples and talk face-to-face with the manufacturers' technologies, which is the most direct experience.

View cases on online platform: Nowadays, many manufacturers will publish their works on Douyin, video accounts or some design platforms. Watch their real-life cases, especially the videos of the processing process, to see their craftsmanship and care. Just looking at the refined renderings is not enough.

B2B platforms such as 1688: There are many manufacturers here, so it is suitable to look for products or materials with a high degree of standardization. Pay attention to screening, focusing on the number of years the store has been open, customer reviews (especially those with pictures), and whether they can provide customized services. You can send an inquiry to compare several companies.

"Three Questions about the Soul" of Inspecting Manufacturers”

After finding several potential manufacturers, how do you determine whether they are reliable? Don’t just look at the price, I usually focus on these three aspects:

Look at the "lizi" - workshop and equipment If conditions permit, be sure to go to the factory to see if it is clean and orderly? Is the equipment new or old? Are there professional laser cutting machines, bending machines, welding, polishing, and painting rooms? It is difficult for a workshop with chaotic management to produce exquisite products. Look at the goods they are making. The details can best reveal the true level.

Look at “face” – past cases and samples Ask them to provide photos or videos of real cases that they have done recently that are similar to your needs. It is best to see the real thing, and directly ask them to send sample books with different materials and processes. Feel whether the corners of the samples are smooth and flat, whether the paint surface is uniform, and whether the welding points are clean. The samples are the most intuitive "resume".

Talk about "details" - communication and quotation When communicating with sales or technology, state your needs clearly and see if the other party is eager to close the deal or is willing to take the time to understand your specific application scenarios and put forward professional suggestions. A detailed quotation can also tell the clues.: Is it generally written "stainless steel sign XX yuan", or is it a clear list of material model (such as 304 or 201 stainless steel), thickness, process steps (cutting, bending, welding, polishing, electroplating, painting, etc.), size, quantity, installation method, etc.? The latter also shows that they are professional, transparent and have less hassle in the later stage.

The last few truths

You get what you pay for It is an iron rule in the metal processing industry that if the price is too low, it is likely to cut corners on material thickness, surface treatment or process details.

Communicate clearly and take it as evidence , all requirements, including material, workmanship, size, color (it is best to provide Pantone color number or physical color sample), construction period, acceptance criteria, and payment method, must be written in the contract. Verbal agreements are unreliable.

Small batch first trial order , if the project is large or you are working with a new manufacturer, you might as well place a small order first to test their quality, construction period and service response.

Finding a metal sign manufacturer is, in the final analysis, a task that requires some thought. It is not like buying standard products, but more like a small "project cooperation". If you choose the right partner, you will not only get a good brand, but also save a lot of worry in the whole process. I hope these few thoughts can help you clarify your thoughts and find the reliable supplier that is most suitable for you. If you have any specific questions, please feel free to chat at any time.