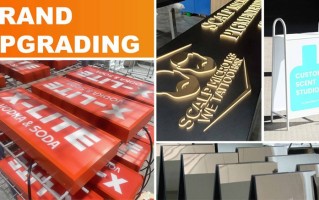

Do you often see those glowing indicator signs in shopping malls, office buildings or factories? Not only are they clear and eye-catching, but they can also provide clear guidance in the dark. I will take you into the world of making acrylic indicator signs and see how these luminous signs we see every day are transformed from drawings into real objects step by step.

.jpg)

first step: Design concept and plan determination

When making any sign, design is always the first step. For acrylic indicator signs, the design must not only consider aesthetics, but also functionality. The designer needs to fully communicate with the customer to understand where the sign will be used, whether it is a safety exit indication, an equipment status display, or a regional guidance sign.

There are actually quite a few things to consider in the design stage, such as the appropriate size - too small to see clearly, too large to waste space and materials. Color matching is also critical. Different colors have very different visual effects in different environments, and some industries have clear specifications for the color of indicator lights. For example, red usually means stop or warning, and green means safety or passage.

The choice of fonts cannot be careless. The text on the indicator light must be clear and easy to read. Sometimes it can be recognized at a distance or in poor light. I have seen some signs with very fancy designs. From a distance, it is impossible to tell what is written, which loses the basic function of instructions.

Step 2: Material preparation and selection

After the design drawing is confirmed, it is time to prepare materials. The main material of acrylic indicator signs is of course acrylic board, but you may not know that there are many types of acrylic boards.

Ordinary acrylic sheets are relatively cheap, but their light transmittance and weather resistance are average. ; The light-guiding acrylic board is specially designed for light-emitting signs. The light spreads more evenly within the board, and there will be no local over-brightness or over-darkness. If it is an outdoor indicator sign, you must choose an outdoor-grade acrylic material that is resistant to ultraviolet rays and high and low temperatures. Otherwise, it will turn yellow and become brittle in a short time.

In addition to acrylic boards, indicator signs also require supporting materials such as LED light sources, power supplies, controllers, metal or plastic frames. LED lights are now basically standard because they save power, have long lifespan, and generate little heat. However, LED lights also have different specifications. You should choose the appropriate model according to the size and brightness requirements of the sign.

Step 3: Processing and manufacturing process

After the materials are ready, the real production begins. This process usually includes cutting, carving, polishing, assembly and other links.

Cut and shape : According to the design drawings, use a laser cutting machine or CNC engraving machine to cut the acrylic plate into the required shape. Laser cutting has high precision and smooth edges, and is suitable for complex shapes. ; CNC engraving can complete surface engraving while cutting.

Text pattern processing : The text and patterns on the indicator lights are usually realized through screen printing, UV printing or engraving and filling. Screen printing is low cost and suitable for mass production. ; UV printing can achieve complex gradient colors and patterns ; For engraving and filling, you first carve out the groove and then fill it with special paint to achieve a three-dimensional and long-lasting effect.

edge processing : The edges of the cut acrylic are relatively rough and need to be flame polished or mechanically polished to make them smooth and transparent. This step is very important and directly affects the appearance and texture of the finished product.

.jpg)

Circuit installation : This is the core step of the indicator sign. Technicians need to install and fix the LED light strips or lamp beads according to the designed position, and then connect the wires, power supply and controller. If the indicator light needs to flash or change color, the control mode must be programmed.

I remember once visiting the production workshop and seeing the workers carefully welding those tiny LED beads. Each solder joint had to be checked repeatedly, because as long as there is a bad contact, the entire sign may not light up or have uneven brightness.

Step 4: Assembly and testing

After all components are produced, the assembly stage begins. The acrylic panel, light source assembly, back panel and other parts are assembled in order and fixed with screws or special glue. Pay special attention to sealing during assembly, especially signs for outdoor use, which must be waterproof and dustproof.

After the assembly is completed, it is not packaged and shipped immediately, but strict testing is carried out. The power-on test is the most basic - check whether all the lights are on normally, whether the brightness is uniform, and whether the color is correct. Then there is the functional test, such as whether the flashing frequency and color change are normal. If it is a touch or induction indicator light, the sensitivity of the sensor must also be tested.

Finally, an aging test must be done to let the sign work continuously for a period of time to simulate actual usage and ensure that there are no potential problems. I once asked a senior craftsman in the factory why the test must be so strict, and he said: “Many of these indicator lights are used in important places, such as safety exits and emergency equipment indicators. If they do not light up at critical moments, big problems may occur. ”

Step 5: Installation and maintenance

After the completed indicator sign is delivered to the place of use, installation is also a matter of course. The installation location, height, and angle must be considered to ensure that it can be clearly seen at the target distance and angle. The power supply access must be safe and standardized. Especially for outdoor installation, lightning and surge protection measures must be taken.

Many people think that the sign is installed and done. In fact, daily maintenance is also very important. Regularly clean the surface dust, check whether the fasteners are loose, and replace aging parts in time. A good acrylic indicator sign can last for five to eight years, but only if it is used and maintained correctly.

The little details in production

Having said so many processes, there are actually many small details that are easily overlooked during the production process. For example, the protective film of the acrylic plate must be removed at the end, otherwise the surface will be easily scratched during the processing. ; LED lights must leave a certain amount of space for heat dissipation, otherwise their lifespan will be greatly shortened. ; The joints must be sealed with special glue to prevent water and mist from entering.

The focus of making indicator signs for different purposes is also different. The indicator lights on industrial equipment are required to be earthquake-resistant and high-temperature resistant. ; Indicators in public places should pay attention to energy saving and long life. ; Indicators in commercial spaces may place more emphasis on aesthetics and design.

final thoughts

It is actually quite a sense of accomplishment to watch an acrylic indicator sign transform from a design drawing into a real object, and then install it where it should shine. These little things that we may not pay much attention to in daily life have a set of rigorous production processes and craftsmanship requirements behind them.

Next time you see those luminous signage, you might take a second look and think about the process it went through to get here. From the designer's conception to the worker's careful production, every link embodies professionalism and care. Good signage is not only a signage tool, but also a part of the space environment, silently providing us with convenience and safety.

The production industry is like this. It seems like a simple thing, but it requires a lot of professional knowledge and experience accumulation to do well. This is true for acrylic indicator signs, and it is also true for other types of signs. If you happen to need to make such signs, I hope this article can help you understand the whole process, know what kind of signs are good, and what points you should pay attention to when making them. After all, only by understanding the story behind the product can you better choose and use it, right?