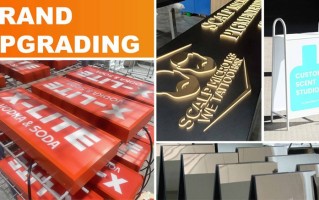

Recently, I have been receiving messages in the background asking if there are any reliable acrylic sign processing manufacturers recommended in Lu'an. Indeed, whether it is the owner of a store or a colleague in charge of publicity in the company, as long as it involves door headers, signage, display boards, etc., acrylic materials are always the best choice. The choice that cannot be avoided - it has good light transmittance, looks high-end, and has good weather resistance, but if you really want to find a suitable processing factory, there are really a lot of things involved. Today we will put aside the official clichés and explain the details from the perspective of an "insider".

We have to understand that acrylic signs sound simple. They are just printing words or cutting shapes on a board, but the process is actually interconnected. Starting from the design draft, to material selection, engraving, cutting, polishing, silk screen or UV printing, to the final transportation and installation, every step may go wrong. When you are looking for a manufacturer in Lu'an, the first thing you should do is not just ask "how much per square meter", that is too amateurish. , you have to first see if they have complete cases, especially if they have made physical objects similar to your needs. It is best to go to the factory and take a look at their equipment. Nowadays, decent factories have to have precision engraving machines and laser cutting machines. If they rely entirely on manual cutting and polishing, the flatness of the edges and the fineness of the details will often not be that interesting, and it will always feel "rough" when installed.

Speaking of materials, acrylic boards are also divided into three, six or nine grades. Things made from new materials and recycled materials may not be visible in the short term, but over time, the recycled materials will easily turn yellow and become brittle, and the light transmittance will also decrease. Some manufacturers offer very low prices, so you have to be careful. It is possible that the materials have been tampered with. , directly ask them what brand of board they use, such as the imported "Ruichang" or the domestically produced "Shenchun". Generally, they dare to use well-known brands, and the quality is relatively guaranteed. Don't be afraid to ask detailed questions. Reliable manufacturers will be happy to explain this to you, because this shows that you are knowledgeable and are not here to compare prices.

.jpg)

Craftsmanship is the key. For example, if the color of the silk screen is not firm, will it fade in a year or two? ; Is UV printing accurate enough? Will the details be blurred? ; Especially the edges after cutting, are they simply ground or finely flame polished? The edge after flame polishing is as translucent as crystal. The cost is a little higher, but the effect and grade are immediately different. For these details, you'd better ask the manufacturer to provide actual scraps that have been made before, touch them, and compare them. It is more effective than listening to a hundred words they say.

.jpg)

Another point that is often overlooked: Communication and cooperation. One of the great advantages of finding a local manufacturer is the ease of communication. Can the design draft be flexibly adjusted according to your ideas? How is the proofing speed? Is the production cycle clear? Some factories agree to everything when they receive an order, but delay everything once they are done. Before placing an order, you might as well try to make one or two small modification requests to see their response speed and attitude. This can often reflect the actual experience of subsequent cooperation.

Finally, let’s talk about “avoiding pitfalls”. There must be problems with ridiculously low prices. Either the materials shrink or the workmanship cuts corners. Don’t be superstitious about the “biggest manufacturer”. Sometimes factories that are too large are not interested in small batches and personalized orders. Suitable, Medium-sized manufacturers that are dedicated and willing to communicate are often the best choice for both cost-effectiveness and effectiveness. The contract or order details must be written clearly, including material specifications, process requirements, construction period, after-sales scope, etc. Written in black and white is a protection for both parties.

When looking for an acrylic sign processing factory in Lu'an, there are three key points.: Look at real objects, ask about details, and communicate , don’t be afraid of trouble, spend more time in the early stage to investigate, and you will save a lot of worry later. After all, a sign will be hung for several years, representing the face of your store or company. This investment is worth a little more thought. I hope these truths can help you find the reliable "right person".