I have been making signs for a long time, and I often get questions from customers.: “I want to make a set of three-dimensional acrylic signs with crystal characters. They look high-end. What kind of manufacturer should I look for? ”Every time I hear this question, I feel that it is really on point. Don’t look at a small three-dimensional sign. From the design drawing to the finished product, there are many doorways in between. If you choose the right processing manufacturer, the effect will be amazing and durable. ; If you choose the wrong one, it may be the beginning of all kinds of troubles - the wrong size, rough corners, yellowing and cracking after a short time... Let's put aside those fancy advertising slogans and talk about what to look for when looking for a reliable crystal letter acrylic three-dimensional sign processing manufacturer.

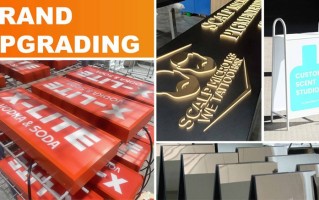

We have to understand what a "crystal three-dimensional acrylic sign" is. To put it simply, it is usually made of an acrylic plate as the base, with a layer of crystal-clear words or graphics that resemble crystal effects glued on it. A good finished product has a strong three-dimensional effect, high transparency, and smooth edges like polished jade, especially under the light. That kind of texture can instantly raise the level of a store or company, but to achieve this effect, materials and craftsmanship are indispensable.

.jpg)

The material is the basis, acrylic board. There is a huge difference in the market from recycled boards that cost a few yuan per kilogram to imported boards that cost hundreds For sources or samples, you can’t just find some transparent plastic for crystal characters. Its hardness, light transmittance, and weather resistance are all important. Some small workshops cut corners on materials in order to keep prices down. The finished product may look okay at first glance, but it will show its original shape after being exposed to wind and sun for half a year. Don’t just compare the price, you must ask clearly.: “What material does your home use? ”

.jpg)

Craftsmanship is the soul. Three-dimensional signs are not simply cut and glued. Starting from the computer design file, whether the path planning is reasonable or not will determine how much material is wasted and whether the edge effect is good or not. Cutting requires a precision laser machine or CNC. The stability of the knife path directly affects whether the edges are smooth and rounded or rough. Bonding is a technical job. What kind of glue is used? Is it ordinary chloroform or special shadowless glue? Is the glue applied evenly and are there any bubbles? Was the subsequent polishing and polishing not in place? If one link in these details is missing, the overall effect will be greatly reduced. I have seen characters made by some manufacturers. When viewed from the side, there are obvious traces of glue, like a "snot" hanging on them, which really affects the appearance. The masters of good manufacturers have many years of experience and are accurate in their hands. The things they make are perfectly integrated and integrated.

.jpg)

So how to judge whether the manufacturer's workmanship is good? Just listening to him won't work, there are a few ways: The first is to look at the cases and ask him to send actual pictures or videos of recent work, especially close-ups of details. ; Second, if possible, go to the factory for a tour (or watch the video) to see if the workshop equipment is professional and how the on-site semi-finished products perform. ; The third is to ask them about their experience in processing complex graphics and special sizes. An experienced manufacturer can quickly provide reasonable process suggestions and solutions to your various needs, instead of just saying "can do everything".

In addition to materials and processes, the "soft power" of the manufacturer is also critical, such as whether the communication is smooth, from confirming the design draft to confirming the process details, and then providing feedback on the production progress. Whether the communication efficiency is high and whether you are patient or not will directly affect your experience and whether the final product meets expectations. Some manufacturers' salesmen know only a little about the process, and they will pass on everything they say. If you don't know clearly, problems may arise later. For example, if the delivery date is on time, integrity is important in business. If you agree on ten days but delay it for half a month, your installation plan and after-sales service will be delayed. In case of minor bumps in transportation or minor problems after installation, whether the manufacturer is willing to actively solve them will show the responsibility of a manufacturer.

Let’s talk about the price. This is definitely what everyone is concerned about. My suggestion is to negotiate the price on the premise of ensuring the materials and workmanship. Don’t try to be cheap and fall into the “low price trap”. A good set of three-dimensional signage is the face of a store or company and needs to be used several times. If you spend a little more money, you will get peace of mind, long-term effects, and professional services. You can find quotes from several reliable manufacturers, comprehensively compare their plans, materials, and prices, and choose the one with the best price/performance ratio, not the one with the lowest price.

Looking for a crystal acrylic three-dimensional sign processing manufacturer is like looking for a partner. He must understand materials, fine craftsmanship, value credibility, and be good at communication. Next time you need to do something, you might as well consider these aspects. After all, an excellent sign is not only a display of information, but also a silent declaration of quality. I hope this sharing can help you avoid detours and find the "right person" who can perfectly present your ideas.