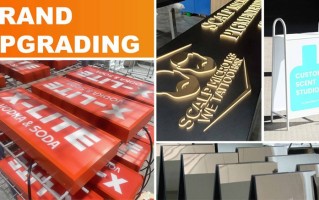

Making acrylic signs sounds pretty simple, right? It's not just cutting boards and printing some words, but those who have actually done this, or have suffered losses when customizing their own signs, will know that there is a lot of depth inside. Behind a refreshing and high-end acrylic sign, from idea to implementation, there are people who have mastered every step. "Carry the trouble", today we will put aside those empty and beautiful words and talk about the five major "meta-responsibility" in acrylic sign production. If we understand these, whether we place orders ourselves or communicate with customers, we can avoid many pitfalls.

.jpg)

First responsibility: Design - Don’t let “taken for granted” ruin your first impression

Design is the source, and this responsibility must first be shouldered by someone. Many people think that design is just about drawing a picture. But the design of acrylic signage is really not just about pulling out a box and typing in a few words. The designer must understand the material. How thick is acrylic? 3mm, 5mm or 8mm? The thickness directly affects the three-dimensional feeling and the way the corners are processed. Is it made transparent, colored or engraved inside? Different effects have very different requirements for post-production processes. Should I choose thin line font or thick bold font? On acrylic, lines that are too thin may not be carved or may break easily, and lines that are too thick may appear bulky. There is also the color, which looks bright blue on the computer. Will the actual acrylic become darker due to thickness and light transmittance? If a designer just sits in front of the computer and "takes these details for granted", the resulting design draft is likely to be a "beautiful trap" that the factory cannot produce at all, or it may not taste like it at all. Responsible design must be based on a full understanding of the characteristics of acrylic and post-processing, otherwise it will be a lack of the first responsibility.

Secondary responsibility: Material selection - if the foundation is not strong, the earth will shake.

.jpg)

When it comes to materials, we have a heavy responsibility. Acrylic boards have many aliases, such as plexiglass, acrylic, etc., but the water here is quite deep. There are new materials and recycled materials, domestic boards and imported boards (such as the famous German Seth and Japanese Mitsubishi). The new materials have excellent permeability, strong weather resistance, and are not prone to yellowing and brittleness. ; Recycled materials are cheap, but they may change beyond recognition within a short period of time, turning yellow, fogging, or even cracking. You say a house number becomes blurry after half a year of use, and customers come to your door. Who is responsible for this? The responsible approach is to clearly recommend the appropriate board based on the use scenario of the sign (indoor or outdoor), budget and expected lifespan. If it is for outdoor use, it must use good UV resistance. ; To maintain high translucency for a long time, brand-new materials are the bottom line. This cannot be ambiguous. The money saved on materials will be doubled in the future in terms of reputation and after-sales.

third party responsibility: Craftsmanship - details are the devil, craftsmanship is the truth

When acrylic arrives in the workshop, the responsibility of the craftsmanship is tested. Cutting is the first step. Should it be cut with a laser or a mechanical engraving machine? Laser cutting has smooth edges and automatic edge sealing, which is highly efficient but also costly. ; Mechanical cutting may cause slight chipping, which requires subsequent manual polishing. This choice must be determined based on accuracy requirements and budget. Then comes engraving or silk screen printing. The depth and intensity of the engraving must be uniform, especially for back engraving (engraving from the back, the three-dimensional characters are seen from the front). If the depth is not grasped well, the front effect will be greatly reduced. For silk screen printing, how is the adhesion and scratch resistance of the ink? Are the colors accurate? Especially when doing multi-layer color overprinting, everything will be ruined if the alignment is not accurate. There is also polishing. Are the corners straight, beveled or rounded? Whether the polishing is in place directly determines whether the sign is a "handicraft" or a "rough product." In these process steps, the craftsmanship and responsibility of each operator are directly imprinted on the finished product.

.jpg)

Fourth element of responsibility: Assembly and quality inspection - the last line of defense to maintain reputation

The parts are all ready, and assembly and quality inspection are the last and most critical line of defense. If it is a multi-layer acrylic sign, what kind of glue is used? Is it a special shadowless glue (UV glue) or an ordinary one? Are there any bubbles during gluing? Is it aligned? These require extremely meticulous operations. After the signs are assembled, the quality inspector must have a sharp eye. Are there any scratches? Are there any tiny bubbles or impurities? Is the color right? Are the dimensional errors within the allowable range? Especially for translucent signs, it is best to check the effect in a light environment similar to actual use. If this check is not strict, all previous efforts may be in vain. If a defective sign is delivered to the customer, no matter how pleasant the previous communication is, it will be zero. Responsible manufacturers will treat quality inspection as an independent and serious link, rather than just a formality.

fifth yuan responsibility: Communication and delivery - beginning to end, closed loop of responsibility

This responsibility is often overlooked, but it runs through the whole process to understand the customer's needs from the very beginning (what problem does he want this sign to solve? Is it to enhance the brand image or simply to indicate the direction? ), communicate the process feasibility and material selection in a timely manner during the process, and then provide clear installation guidance and even maintenance suggestions during the final delivery. This constitutes a complete closed loop of responsibility. The most feared thing is that you don’t ask in the early stage, don’t talk in the mid-term, and ignore it in the later stage. For example, if the customer wants to use it outdoors, you don’t ask, you do it according to indoor standards, and it breaks down not long after installation. How to divide this responsibility? Or, for a sign that is installed in a special shape, you do not provide an installation diagram. If the customer installs it crookedly and the effect is not good, he will also think that it is a problem with your product. Responsible communication is to make the information symmetrical, manage the customer's expectations, and draw a successful conclusion during delivery.

Therefore, regardless of looking at a small acrylic sign, it is the product of a "community of responsibilities". Design, material selection, craftsmanship, quality inspection, and communication are all five "meta-responsibility" that are intertwined. If any link is missing, the final work may not be satisfactory. As a demander, when we are looking for a partner, we might as well examine it from these five dimensions. ; As a producer, you must clarify your responsibilities in every link and strive for excellence. After all, signage is a silent spokesperson, and its quality speaks directly for you.