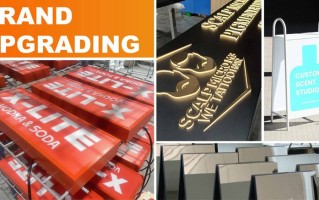

Friends who are in the metal signage industry probably have a lot of headaches with screen printing equipment. The logo the customer wants must be bright in color, with clear lines, and it must withstand the sun and rain. If the product does not turn out well and the customer is dissatisfied, the order may be rejected. ; The machine always breaks down, delaying the production progress, which makes people even more angry. After all, a reliable screen printing machine often has a more reliable equipment manufacturer behind it. Today, we will not talk about those imaginary parameters. We will combine our daily visits to the factory and chatting with colleagues to talk about the things worth paying attention to when looking for metal sign screen printing machinery and equipment manufacturers.

First of all, you must understand that metal sign screen printing is not the same as ordinary paper or cloth printing. The metal surface is usually smoother and harder, and some have curvature or special coatings. This has special requirements for the adhesion of the ink, the tension of the screen, the pressure of the scraper and even the drying method. If you go to a manufacturer that mainly makes T-shirt printing machines, their machines may be cheap, but when used on metal signs, they are likely to be "acclimated", and problems such as weak printing and easy scratching will ensue. Manufacturers specializing in metal printing, their equipment is often optimized in detail , the workbench may have magnetic or vacuum adsorption to ensure that the metal plate does not move during the printing process. ; The drying system will consider the thermal conductivity characteristics of metal to avoid sudden changes in temperature that may cause ink cracking or plate deformation. These experiences are not gained by simply modifying general equipment, but are accumulated and debugged little by little through long-term service to the metal processing industry.

.jpg)

How to judge whether a manufacturer is "right"? Just looking at the website and brochures is not enough. I think there are a few points that are particularly practical.:

.jpg)

First, Look at the cases, but also look at the handling of "failure" cases , reliable manufacturers are happy to display successful works, but you might as well ask more: “Have you ever encountered unsatisfactory printing results on certain special metals (such as brushed stainless steel, anodized aluminum)? How did you solve it? ” Manufacturers that can honestly share technical difficulties and solutions usually have a solid technical foundation and are more willing to take responsibility for after-sales service. On the contrary, those who boast that their own equipment is omnipotent and flawless should be careful. The machine is for use, not for supply. It is normal to encounter problems in actual production. The key depends on whether the manufacturer has the ability and attitude to help you solve it.

.jpg)

second, Don’t just listen to what the sales say, look for opportunities to listen to the “dialects” of their technical masters.” , sales words are often packaged, but the words of technicians who actually debug and repair equipment, especially old masters, are more "down-to-earth" and can better reflect the real situation of the equipment and the technical accumulation of the manufacturer. He may tell you: “We use a certain brand of pneumatic components for this machine. Although they are more expensive, they are much more stable than cheap ones and are not prone to air leakage. The adjusted pressure value can be maintained for a long time. ” Or remind you: “If you mainly print small-size signs, the lifting stroke of the screen frame of this model is a bit large, and the operation is a bit slow. You can take a look at our other model optimized for small parts. ” This kind of detail may not be included in the sales brochure, but it is the key to determining whether you can use it or not.

third, Treat "after-sales service" as part of the equipment After the screen printing equipment has been used for a long time, the scraper is worn, the screen needs to be calibrated, and the sensor may malfunction. These are common things. The response speed of the manufacturer, the professionalism of the maintenance personnel, and the adequacy of the supply of spare parts directly affect your shutdown time. Some manufacturers are enthusiastic when selling equipment, but if there is a problem, they will push back and forth, or the maintenance personnel are not good enough, and small problems can become big problems. A better way is to know clearly before buying: How long is the warranty period? Is there clear guidance or training for routine maintenance? Are commonly used accessories easily available and transparently priced? Can remote guidance or quick door-to-door guidance be provided for emergency failures? Strong manufacturers often have a mature system in these aspects and can even train one or two basic operation and maintenance personnel for you.

Now the industry is also changing. In addition to traditional precision manual screen printing machines and semi-automatic screen printing machines, for large-volume metal signs, fully automatic visual alignment screen printing lines are also beginning to be mentioned more. This requires higher comprehensive capabilities of manufacturers, not only involving machinery, but also optical positioning, software control, etc. If you have needs in this area, you should also check whether the manufacturer has successful integration cases and whether their technical team can provide full support from process trial production to mass production optimization.

Finding a metal sign screen printing machinery and equipment manufacturer is a bit like finding a partner. Price is important, but it is by no means the only criterion , a manufacturer with solid technology, attention to details, and willingness to solve practical problems for you. Even if the initial investment in equipment is slightly higher, in the long run, the production stability, product quality assurance and trouble-free experience it can bring you are worth far more than the price difference. After all, we buy equipment to do business better, not to bring back an "ancestor" who needs to be served every day, don't you think? Run around more, read more, and chat with people in different positions at the manufacturer, so that you can have a better understanding. I hope this superficial experience can help you avoid detours when making your choice.