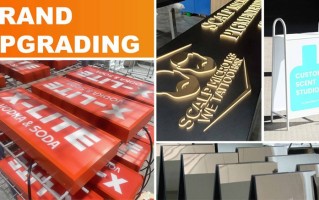

Hey, recently many friends are asking about it backstage and on WeChat.: “Editor, do you have any recommendations for reliable acrylic sign manufacturers in Northeast China? Urgent call! ” Every time I see messages like this, I understand everyone's rush to find a supplier. It may be that the store is in a hurry to open, or the project is waiting for acceptance. I want to find a manufacturer immediately, and the matter will be settled as soon as I make a call.

.jpg)

But to be honest, after working on content for so many years and having contact with so many producers and customers, I really feel that, Asking for the phone number directly may be the "slowest" way. , think about it, the Northeast region is so big, Heilongjiang, Jilin, Liaoning, there are factories that make acrylic in every place. The level, price, and areas of expertise are really different. What can you say if you just hold a phone number in your hand? Is the other end of the phone a formal factory or a family workshop? Are you good at precision craftsmanship or do you mainly make high-volume low-end goods? If you don’t know everything you ask, communication will be inefficient and it’s easy to get into trouble.

So today, instead of giving you a number directly (that would be too irresponsible), let’s have a chat. Before you want to call that Northeastern acrylic sign manufacturer, Which doorways should we find out? , once you understand these things and contact me again, you will definitely get twice the result with half the effort and the conversation will be tough.

First, don’t be fooled by the big concept of “Northeast”, it depends on the specific location. The industrial foundation of the Northeast is indeed good, but when it comes to the subdivision of acrylic signs, the agglomeration effect is quite obvious. In some areas, the supply of raw materials for panels is convenient, while in other areas, due to historical reasons, a large number of skilled craftsmen who make signs and signs have gathered. If you want to do a large-scale outdoor project, you may have to find a factory with convenient logistics and large equipment that can handle thick plate splicing. ; If it is mainly about indoor exquisite display boards and signboards, then the precision requirements for detail polishing, silk screen printing or UV printing are higher. You must first clarify your core needs, which is more important. Cost advantage, process accuracy or logistics timeliness? ? In this way, you can have a preliminary screening when looking, instead of aimlessly searching for "Northeast manufacturers".

Second, behind the three words "acrylic", there is a lot of knowledge. This is the most easily overlooked area and the most likely to cause disputes. Ask on the phone: “How much does it cost per square meter to make it out of acrylic? ” The manufacturer quoted a price, and you thought it was quite cheap, and it was fine. But when the goods arrived, you were dumbfounded. The brand was yellowed, it felt thin, and the cutting edge was rough. Why? Because acrylic is also divided into new materials, recycled materials, domestic materials, imported materials, ordinary boards and anti-UV boards, etc. Made of recycled materials, it cannot be seen in the short term. It will "reveal its original shape" after being exposed to the sun for half a year. Responsible manufacturers will ask about the usage environment and give material suggestions when you consult. They only focus on low prices to grab orders. I hope you use the cheapest materials. When you call in the future, don't just ask about the price, but ask more questions.: “ What specifications and brand of boards do you recommend? Why? ” You can hear the professionalism and sincerity from the other party's answer.

.jpg)

Third, the details of the craftsmanship are where the true capabilities of the manufacturer are reflected. Acrylic signs are not simply cut into shapes. Is the cutting done by laser or engraving? Are the edges polished or flame polished? What is the light transmittance after polishing? Should I use color plates directly, or do I need silk screen printing or UV printing? What is the adhesion and wear resistance of silk screen printing? Will the UV printed pattern be easily scratched off? Do I need to do multi-layer lamination and three-dimensional hollowing? These process details directly determine the high-end feel and durability of the finished product. Experienced manufacturers will take the initiative to ask about your design draft and point out where the process can be better realized and where there may be risks that need to be adjusted. For those who will answer "No problem, we can do it" no matter what you say, you have to be careful. When communicating on the phone, you might as well Ask about the one or two details that are the most complicated and worrying about your design. , see how the other party answers, this is the touchstone.

Fourth, proofing and factory visits are more effective than ten thousand phone calls. If the quantity is relatively large, or the project is important, I strongly recommend that you don’t save on the sampling fee and travel expenses, but ask the interested manufacturer to make a sample. The actual product is in hand, and the texture, color, and craftsmanship level are clear at a glance. If you have the opportunity, go to the factory in person or ask someone to see whether the workshop is clean and orderly, how well the equipment is maintained, and what the quality of the work the workers are doing is like. This is called“ seeing is believing ”, some small workshops boast a lot over the phone, but the truth is revealed as soon as they see the scene. On-site inspections can also help you feel the manufacturer's management style and smooth communication, which is much more real than trying to figure it out on the phone.

Fifth, when communicating, don’t just talk about business, but also talk about “people.” The last point, this is my personal experience, it is very important to find a long-term partner. When talking on the phone or WeChat, feel the other party's communication attitude. Is it patient and meticulous, or impatient? Are you willing to help you solve problems and optimize solutions, or do you just want to make a quick quote and close the deal? A good contact person is even more important than the size of the manufacturer. He understands technology and materials, and can think about problems from your perspective. This kind of cooperation is worry-free. If you encounter someone who gets impatient after asking a few questions, or can't explain anything clearly, no matter how low the price is, it may cause a lot of trouble in the future.

Okay, after talking so much, it seems I haven’t given you my phone number yet, right? That's right! My original intention is that before you pick up the phone, Become a “knowledgeable” purchaser yourself first , when you have clarified your needs, learned a little about the industry, and then proactively search and screen, whether through industry B2B websites, searching for local business information, or asking peers to recommend you, you will be more confident and efficient in finding the Northeast acrylic sign manufacturer that is truly suitable for you.

At that time, it is not that you rush to ask him for a phone call, but that you can calmly put forward your requirements and listen to his professional plan. Only that phone call will be a truly efficient and valuable start. I wish you good luck and hope you can find that reliable partner!