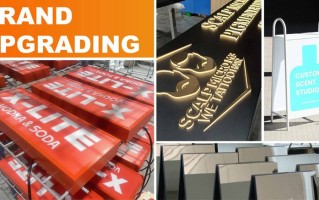

Recently I have received a lot of messages backstage, and the most frequently asked questions are:: “How much does it cost to sell metal signs directly from the manufacturer? ” After a casual search, there are all kinds of price lists flying all over the Internet, ranging from a few cents to hundreds of dollars each. It is dazzling to see. To be honest, this industry is quite deep. If you just stare at the price numbers, you may accidentally step into a trap. Today, we will put aside those fancy advertisements and talk to you about the things behind the factory direct sales price lists from the perspective of an industry insider.

.jpg)

First, pour some cold water on it: There is no one-size-fits-all price list for metal signs. You see those that directly price "stainless steel plate XX yuan/square meter" or "bronze plate XXX yuan/piece", most of them are gimmicks to attract traffic, or have numerous additional conditions hidden. Really reliable manufacturers will definitely ask a lot of details before quoting. Why? Because the price of metal signs is made up of a bunch of factors like building blocks. If you move one, the total price will change.

first building block: The cost of materials is the big one and the most tricky part. Material costs account for the bulk of the entire cost. The prices of commonly used stainless steel, copper, aluminum, and iron are quite different.

.jpg)

Stainless steel: 304 and 201 look similar, but the price and rust resistance are very different. The manufacturer reports it as "304". If you actually use 201, the price will drop immediately. But after a year and a half of use, it will be rusty. Who do you go to?

copper: More complicated, copper, brass, imitation copper, bronze, and the thickness of the copper (called "sufficiently thick" in the industry), the price increases layer by layer. Some low-priced products may make a fuss about the thickness, or use plated copper instead of solid copper. The appearance is difficult to distinguish in the short term, but the texture and durability are completely different.

aluminum plate: Ordinary aluminum plates and imported high-grade aluminum plates have completely different textures and flatness after oxidation. Looking at the price list, you must first lock in “Material Type" and "Specific Specification Thickness” , always put a question mark if anything is vague. The advantage of direct sales from manufacturers lies in the large scale of material procurement and lower costs, but the premise is that it must use this benefit on the real materials you require.

second building block: Process complexity is the "amplifier" of price. The material is the canvas, and the craftsmanship is the painting on it. The craftsmanship directly determines the cost of labor and time.

Basic cutting: Wire cutting, laser cutting, and waterjet cutting, the accuracy and cost are increasing. Simple square laser cutting is very cheap, but if you have a complex special-shaped logo, the cutting path is long, time-consuming and energy-consuming, and the price will go up.

surface treatment: This is the key to appearance and price. Polishing (mirror surface, brushed), sandblasting, electroplating (titanium gold plating, rose gold), baking paint, antique distressing, etching and filling... The price of each process is different. The cost of a simple silk screen coloring and a set of multi-color overprinting + baking paint can be several times different. The etching depth is different, and the price is also different.

Post assembly: Is it just a flat brand, or does it require bending, welding, and assembling a multi-layer structure? Do I need to add a back panel, a bracket, or built-in LED lights? Every additional step is worth real money.

The third building block: Design difficulty and minimum order quantity. Don't think that if you provide the design draft, the manufacturer will save trouble. Is your design draft suitable for the production process? Are the lines too thin for the laser to cut? Is it difficult to align the overprinting with too many colors? Manufacturers need to do process audits and file conversions, and complex artwork processing also requires charges. More importantly, Minimum order quantity , the reason why factory direct selling is cheap is that it is based on small profits but quick turnover. If you only make one or two pieces, the cost of starting up, plate making, and adjusting the machine cannot be shared, so the unit price must be high. The larger the quantity, the thinner the fixed cost allocation in the unit price. This is the core advantage of factory direct selling. For those who claim "wholesale price for one piece", you have to think about whether they are second-rate dealers, or have made up for it in other links.

.jpg)

The fourth building block: Hidden costs and services. This part is often invisible on the price list, but it directly affects the total price and experience.

freight: For large, heavy and special-shaped items, the packaging and transportation costs are high. Is it payable on delivery or tax-included shipping?

Proofing fee: There is usually a charge for proofing before a bulk order, which may be deducted after the large manufacturer places the order. This is a business rule.

After-sales and warranty: Regular manufacturers will provide a certain period of warranty (such as outdoor weather resistance), and these costs are actually included in the quotation system. If you blindly fight for low prices, the warranty is likely to be empty talk.

bill: Do you want a regular invoice or a special VAT invoice? The tax points are different.

How to get a reliable "price list" from manufacturers?

Prepare clear requirements: Don’t just say “I want a stainless steel sign”, be as clear as possible: Material (such as 304 stainless steel, 1.5mm thick), size (length, width, and height), process (such as laser cutting + mirror polishing + dark paint crossword), quantity, and usage environment (indoor/outdoor).

Provide design draft: Provide vector files (AI/CDR) where possible and state the desired effect.

Comprehensive price inquiry: Ask the other party to provide Itemized quotation , that is, how much are the material fees, processing fees, surface treatment fees, and other miscellaneous fees, so that you know where the money is spent, and it is also convenient to compare different manufacturers.

Inquire about samples and minimum order quantity: Ask about the sampling policy and fees, as well as the unit prices for different quantity gradients.

Look at the case and ask for details: Don't just look at the price figures, look at the actual cases that the manufacturers have done, especially those with similar needs to yours. Ask them how they solved a certain process difficulty. You will know their professionalism right away.

In the final analysis, find a metal sign manufacturer to sell directly, the picture is Cost-effectiveness ,no Absolutely low price , a responsible price list should be a clear and transparent cost accounting list customized based on your specific needs. It should be like a physical examination report, with clear indicators, rather than a general advertising leaflet.

The next time I see the temptation of "one price for all", I feel a lot of worry. In the manufacturing industry, negotiating price without specific craftsmanship and quality is basically equivalent to being a rogue. Take the time to communicate clearly about the details, and get a sign that lasts a long time, is easy to see, and truly embodies value. It is worth it no matter how you calculate it. After all, a sign is not only an information mark, but also a silent spokesperson for your brand and taste, right?