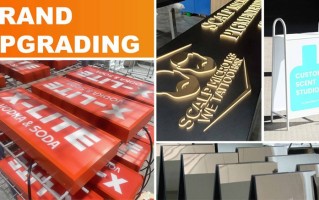

Recently, I have received many messages from readers asking about the customization of acrylic electric control box signs. Especially many friends from the factory equipment department, purchasers from automation companies, and technicians who upgrade their own equipment are always struggling with one question.: Should we go directly to the manufacturer for customization, or go through an intermediary such as an advertising agency or design studio? Today we will break it open and crush it to talk about the secrets inside, and share some practical experience by the way - there are some pitfalls, and you will only know the pain after stepping on them.

Let’s first talk about why acrylic has become a “frequent customer” for electrical control box signs. Its scientific name is polymethylmethacrylate, which sounds a bit awkward, but its advantages are indeed obvious. It has good light transmittance and is as bright as glass, but it is much lighter than glass and can withstand drops. For outdoor use, its UV resistance is much stronger than ordinary plastic, and it is not easy to yellow and become brittle. The most important thing is that it is easy to process! Cutting, engraving, silk screen printing, UV printing, everything is possible. The resulting logo is clear and durable. When attached to the electrical control box, it is both eye-catching and professional. Therefore, it can be seen everywhere in factory workshops, power distribution rooms, and automated production lines.

.jpg)

The customization industry is quite complex. I have come into contact with many customers. At first, they wanted to save trouble or were attracted by the low price, so they found a middleman, but ended up having a lot of troubles. For example, Lao Li, their factory upgraded the production line last year and needed to make a batch of acrylic signs with circuit diagrams. He found a local advertising company, and the price was negotiated very happily. The delivery was also fast, but within two months of installation, the problem came.: The silk-screened line symbols are a bit blurry, and the key interface logos can’t be seen clearly in the dark areas of the workshop. ; What's even worse is that the corners of some signs were not polished smooth, and the installer accidentally scratched his hand. Lao Li went to the advertising company, and the other party was very kind. But when it came to the actual solution, they blamed "material characteristics" or "process limits", and they argued back and forth. Finally, they found out that the advertising company had also outsourced it to a small workshop, and there was no way to control the quality. Lao Li regretted it.: “If I had known this, it would have been better to spend more time and find a reliable manufacturer directly. ”

So if you directly go to the manufacturer to customize it, will you be able to sit back and relax? Not necessarily, there is a huge difference between manufacturers. Some so-called "factory direct sales" may be small processing stations with crude equipment and technology that is stuck a few years ago. If you send a more complicated vector diagram, they may not be able to output it perfectly. How to choose becomes the key.

Don’t just focus on the price. You get what you pay for is an iron rule in the manufacturing industry. If a company’s quotation is significantly lower than the market average, you have to be careful. Is it using recycled materials or inferior boards? Is the ink cheap and fades easily? Are corners cut in the workmanship, for example, what should be polished is simply cut? These will directly affect the life and effect of the sign. The electric control box sign is not a decoration. It has to face oil dirt, dust, possible temperature differences and even chemical gases for a long time. If the quality is not up to standard, it will soon be "revealed", and the cost of replacement will be higher.

.jpg)

It depends on the manufacturer's "soft power". One is design and communication skills. A good manufacturer will have professional technical personnel to connect with you and understand your needs. Do you want high temperature resistance? Or do you need a sticker on the back for easy application? Are there any special requirements for color zoning in circuit diagrams? They need to be able to give you advice, not just take what you say, or pretend to understand at all. The other thing is the ability to prototype. Before mass production, can you produce a physical sample to see? This is a touchstone to test the manufacturer's craftsmanship and sincerity. Through the sample, you can intuitively feel the thickness and texture of the material, the clarity of the printing, and the details of the corner processing.

Let’s talk about the process details. Acrylic signs look simple, but there are a lot of things to consider, such as cutting. Should you use a laser or a mechanical knife? The edges cut by laser are smoother and flatter, with high precision and no burrs. For example, silk screen printing, color registration is accurate, and the ink adhesion is strong. Try scraping it with your fingernail (of course, don’t really scratch the human sample). If it is used outdoors, is there any anti-UV treatment? Is the adhesive's viscosity stable under temperature differences? Reliable manufacturers will proactively confirm these details with you without waiting for you to ask.

Another important point is whether the manufacturer can provide supporting services. In addition to acrylic signs, do they also make metal signs and PVC signs? There may be more than one logo on the electrical control box. For another example, do they understand the relevant industry standards? Some specific industries (such as electric power, chemical industry) have regulatory requirements for signage materials, colors, and symbols. An experienced manufacturer can help you avoid these compliance risks.

.jpg)

Finally, let’s talk about the real advantages of “factory direct sales”. In addition to theoretically more transparent prices and fewer intermediate links, the biggest benefit is Responsibilities are clear , if there is a problem, you know who to look for, and you will not be kicked out like Lao Li. From material procurement to processing and production, everything is completed within one system. Quality traceability is also convenient. Direct technical communication with the manufacturer makes modification and adjustment more efficient, and it is easier to realize your customized ideas.

Going directly to the manufacturer may require you to invest more time in early communication, the drawings must be as standardized as possible, and the requirements must be as clear as possible, but this time investment is worth it, and it will give you long-term peace of mind and safety in the future.

Acrylic electric control box sign customization may seem like a small thing, but it directly affects the efficiency and safety of equipment management. There is no absolute answer whether to find a manufacturer or a middleman. The core lies in whether the "supplier" you find is professional, reliable, and responsible. Don’t be fooled by gorgeous words and low quotations. Ask more about the details of the process, look at actual cases, and get a physical sample to weigh and weigh. After all, what is installed on the electrical control box is not only a sign, but also an insistence on safety and professionalism.

I hope these truths can help you feel more confident next time you make customizations. If you have any specific questions, you are welcome to chat at any time and let’s discuss it together.