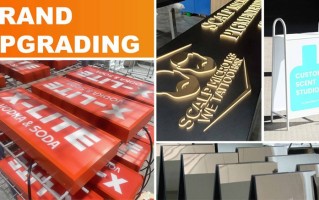

Hey, friends who pay attention to sign production, today we are not going to talk about it, but actually go through how the acrylic sign on the control cabinet turned from a drawing into a finished product. This thing looks simple, isn't it just a board with a few words printed on it? But when it comes to making it, there are a lot of tricks involved, and a little carelessness may affect the overall appearance and even the service life. I spent a few days with the factory masters and went through the whole process, so I will chat with everyone.

.jpg)

We have to start with the design draft. The signage of the control cabinet is not just a random drawing. The size, installation position, and cabinet color must be taken into consideration. Usually we use CAD or Illustrator to draw the drawings, and the borders, hole positions, text, and icons are all accurate to millimeters. Here is a little experience: Because the edges of acrylic will have a slight curvature after cutting, it is best not to place the text too close to the edge when designing, otherwise the finished product will look a bit "squeezed". If the sign needs to be backlit, the design must pay more attention to light transmittance and color layering. These must be clearly marked in the document in advance.

After the design draft is confirmed, the next step is to select materials. Acrylic boards are also divided into three, six, and nine grades. Recycled materials and new materials have far different light transmittance and weather resistance. Control cabinets are often used in industrial environments and may face oil pollution, temperature differences, and even chemical corrosion, so it is generally recommended to use The thickness of imported boards of new materials or domestic high-quality boards is determined according to the size of the sign. 2-3mm is more commonly used. In terms of color, in addition to the common white, black, and gray, there are also many customized colors to choose from, but you must pay attention to the color difference problem during mass production.

.jpg)

Once the materials are in place, it’s time to enter the core production process. The first step is cutting. Nowadays, most people use CNC engraving machines to fix the plates. The machine cuts the cutter accurately according to the design document. This is a test of the master’s experience - the cutting speed and the rotation speed of the cutter head will affect the edge effect. If you cut too fast, the edge will chip, while if you cut too slowly, it may be scorched. A good cutting surface should be smooth and translucent, with no burrs to the touch.

The cut blanks need to be edge processed. The straight edges are simply polished. If you want to make rounded corners or beveled edges, you have to use a chamfering machine or polish them by hand. This step is particularly easy to be ignored, but in fact, the texture of the edges directly affects the overall grade of the sign. I have seen some small factories just grind it twice to save trouble. Once you touch the handle, it looks very cheap to install it.

.jpg)

The next step is to print or engrave graphics and text. If it is silk screen printing, you must first make a plate, adjust the ink, and overprint one color at a time. The advantage of silk screen printing is that the color is solid and durable. It is especially suitable for simple color blocks and text. But if it is complex gradient colors or small batch customization, UV flatbed printing is now used more often. This machine is like a big printer. Directly printing the pattern on the acrylic surface has a delicate effect, and it can also produce color photo-quality patterns. However, although UV ink cures quickly, the adhesion and flatness must be carefully controlled. For some signs that require a concave and convex feeling, an engraving machine will be used to carve out textures of different shades, and then filled or plated with color. The three-dimensional effect cannot be achieved with flat printing.

Before printing is finished, it still depends on whether post-processing is needed. For example, if you need to install LED light strips, you need to slot the wiring on the back. ; For double-sided display, two pieces of acrylic must be combined ; Others need to be covered with a protective film to prevent scratches during transportation. Finally, there is the quality inspection step. Carefully check under the light whether there are scratches, bubbles, color differences, or text errors. The dimensions must also be checked again with a caliper, especially the mounting holes. If there is a difference of one millimeter, it may not fit, and it will be a waste product.

After everything is qualified, the packaging is also very particular. Each sign should be separated by soft paper or bubble wrap to prevent friction. The outer box should be strong, and corners should be protected at corners that are easy to bump. After all, after all the hard work, it would be unjust if something went wrong during transportation.

After running through this entire process, a control cabinet acrylic sign is truly born. It may be just a small part of the equipment, but a good sign is not only clear and durable, but also improves the quality of the entire product. In the final analysis, production requires technology, experience, and care. I hope this article can help you gain a more practical understanding of this industry. Next time you need to make a sign, you will also be able to better understand how to communicate with the manufacturer to ensure that you are getting something truly reliable.