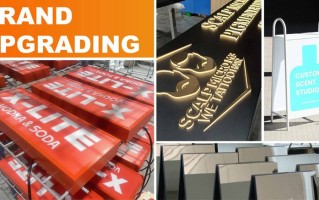

Recently I have received a lot of private messages in the background, and the most frequently asked questions are:: “Editor, our company wants to make a batch of metal laser signs. Which manufacturer should we look for? ”To be honest, this issue cannot be explained clearly in one or two sentences. There are so many manufacturers on the market, ranging from family workshops to large-scale factories, and the prices, craftsmanship and services vary greatly. Today we will put aside those fancy advertisements and talk about what to look for and how to choose when you need to find a metal plate laser signage manufacturer.

We have to understand the difference between "manufacturer" and "processing point".

Many people ask "what manufacturers are there" when they first come up. In fact, you need to understand your needs first. Do you want simple processing with supplied materials, or do you need one-stop service from design, material selection, craftsmanship to after-sales?

.jpg)

If you already have a designed vector diagram in hand and have prepared the materials yourself, but you just need to find a place to cut it out with a laser machine and engrave words, then many small and medium-sized processing centers or even studios can meet the needs. Such places are usually located around hardware processing markets and industrial parks in various places. They are highly flexible, can receive small orders and urgent orders quickly, and the prices are also good. Relatively cheap, but the problem is that their craftsmanship is often single, the quality control may not be stable, and the materials may not be able to give you professional advice. I know a friend who runs a cafe. At first, he found a small workshop to make menu boards for a cheap price. As a result, the stainless steel edges were not passivated, which almost scratched the customers' hands. Later, the rework was even more expensive.

The real "manufacturer" usually refers to one with a certain scale and able to provide Design support, multiple material selections (such as stainless steel, aluminum plate, brass, titanium, etc.), multiple process combinations (laser cutting, engraving, etching, painting, electroplating, antique distressing, etc.) and post-surface treatment (brushing, mirror, sandblasting) Capable production companies often have a fixed material supply chain and have a better understanding of material characteristics and applicable scenarios. For outdoor signs, they will recommend that you use 304 or even 316 stainless steel with better corrosion resistance and do a good job in surface protection. ; For indoor decorative signs, we may recommend more textured brass brushing with laser engraving. Such manufacturers are more common in areas with concentrated manufacturing industries such as Guangdong, Jiangsu, Zhejiang, and Shandong.

How to find and filter specifically?

online channels: Don’t just look at the ads, look at the “traces”.

.jpg)

B2B platform: Established platforms such as Alibaba 1688 and Huicong.com are still the main places to find suppliers, but don’t just look at store decoration and sales rankings, be sure to click on them. “Buyer Show” ——That is, the actual pictures in customer reviews are much more real than the promotional pictures taken by the merchants themselves. Look carefully at the details.: Is the cutting section smooth and free of burrs? Are the engraving lines clear and even? Is the paint surface smooth? Are there any obvious workmanship flaws?

Vertical industry websites and communities: By hanging out in some designer forums, logo industry websites, and even related QQ groups and WeChat groups, and listening to the recommendations and complaints from peers, you can often get more authentic word-of-mouth information. A private evaluation of "this company's delivery is particularly on time" or "that company's after-sales processing is very slow" is more effective than any certificate.

Case library: Reliable manufacturers will definitely show their successful cases to see what types of customers they have served (government projects, corporate buildings, shopping malls, schools, hospitals, etc.) and how complex the cases are. If the cases are all simple house numbers, and what you need is a three-dimensional logo with complex patterns and multi-process combinations, you may have to look again.

Offline inspection: If possible, you must "seeing is believing".

For projects with high budgets, large quantities, and strict requirements, if the manufacturer is not particularly far away, it is strongly recommended to arrange an on-site inspection to see if their production environment is clean and orderly (this reflects the management level and quality control awareness), whether the equipment is advanced and well-maintained (the power and brand of the laser machine directly affect processing accuracy and efficiency), whether there are semi-finished products and finished products in the workshop where you can intuitively feel the quality. Chat with their technical or business personnel to hear their understanding of the process and ideas for solving problems, and whether they are good at it.

Communication and proofing: Touchstone session.

No matter how well we understand it in advance, Proofing It is an essential step. Provide your clear needs (size, material, workmanship, quantity, budget) and let 2-3 interested manufacturers provide proofing. Don’t be afraid to pay the proofing fee. It is normal for regular manufacturers to charge reasonable proofing fees. This can screen out a group of people who just want to make quick money and are not sincere in taking orders. Through proofing, you can directly compare: Whose craftsmanship is more refined? Whose color reproduction is more accurate? Who communicates more smoothly and understands your intentions better? Whose estimate of delivery date is more reliable?

Let’s talk about some common “pitfalls”.

price trap: If the quotation is much lower than the market price, you must be wary. They may cut corners on the material thickness (for example, it claims to use 1.5mm but actually uses 1.2mm), or omit steps in post-processing (such as not doing anti-fingerprint coating or passivation treatment).

Craftsmanship bragging: Turn ordinary laser engraving into "3D three-dimensional engraving" and screen printing into "nano spraying". Ask more about technical details and ask to see physical objects with similar processes.

Delivery date fraud: In order to receive orders, everything is promised to be "no problem, shipped within three days." Laser signage involves multiple processes. The real production cycle needs to be reasonably evaluated and the production process and time nodes must be confirmed in advance.

In the final analysis, when looking for a metal plate laser sign manufacturer, there is no absolute "which one is the best", only "which one is most suitable for your current project". It is not like buying fast-moving consumer goods, but more like a small project cooperation. You have to put some effort into screening, comparing, communicating and verifying from massive information.

I hope this article can give you some direction. If you have specific needs next time, such as whether to make retro bronze medals or modern stainless steel luminous characters, maybe we can talk in depth about the different craftsmanship. After all, this industry is not shallow, but if you find out the way, you can also find many treasure manufacturers.