Over the years of working in the signage industry, I have often been asked by customers: “Are there any reliable acrylic sign manufacturers in the Northeast? ” To be honest, this question seems simple, but if you really want to break it down, you really need to take a closer look. Although the Northeast, a land with profound industrial heritage, is not as densely populated with manufacturers as the southern coastal areas, there are also many down-to-earth companies working quietly. Based on what I have contacted and learned over the years, I will talk to you about the acrylic sign manufacturers in the Northeast.

Overview of Northeast Acrylic Signage Industry

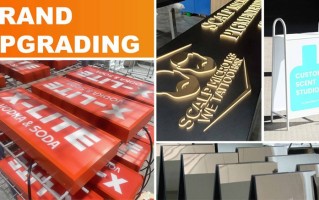

First of all, it must be said that the sign manufacturing industry in Northeast China has its own characteristics. Affected by the climate and industrial tradition, manufacturers here tend to pay more attention to the durability and practicality of products, especially in the resistance to wind, snow and low temperature of outdoor signs. Many manufacturers have unique processes. Acrylic signs have been widely used in shopping malls, enterprises, schools and other places because of their good light transmittance, easy processing, and good visual effects. Local manufacturers have also gradually formed a service chain from material processing to design and production.

.jpg)

However, it must be said objectively that compared with the industrial agglomeration in the Yangtze River Delta and the Pearl River Delta, acrylic sign manufacturers in the Northeast are relatively scattered. They are mainly small and medium-sized enterprises, but there are some old factories with solid technology and good reputations.

A brief analysis of some representative manufacturers

Shenyang area As an important industrial center in the Northeast, Shenyang has several signmaking companies with a long history. For example, an old factory in Tiexi District has been processing signs for almost 20 years. In the early years, they mainly focused on metal signs. Later, they gradually introduced acrylic laser cutting and hot bending processes. Their advantage lies in their experience in adapting to the Northeast climate. For example, in Asia There are some native methods of choosing acrylic adhesives and handling temperature differences in thick plates, and the results are quite real. There are also some emerging advertising production companies in Shenyang. Although they are not large in scale, their equipment and design concepts are relatively new, and they are good at making creative acrylic signs, such as multi-layered three-dimensional characters, luminous signs with built-in LED light sources, etc.

Changchun area Changchun's automobile industry has led to a number of supporting companies, some of which are involved in sign production. I have contacted a small factory in Green Park. The boss used to make molds. After transitioning to acrylic signs, they have advantages in precision control. They can do relatively complex special-shaped cutting, and because of the local chemical material base, they have good cost control in the selection and post-processing of acrylic sheets. However, this type of manufacturer sometimes has weak design capabilities and is more suitable for the cooperation model of drawing processing.

Harbin and surrounding areas I personally feel that acrylic sign manufacturers in Harbin pay more attention to the durability of outdoor applications. After all, the winter here is long and the signs have to withstand the test of low temperature. There is a manufacturer that has been in Daowai District for more than ten years. They will add a layer of anti-U coating on the back of the acrylic. Although the V coating increases the cost, it can effectively slow down the yellowing problem after prolonged exposure to sunlight. Manufacturers in some border cities in Heilongjiang occasionally receive orders for signs for trade with Russia, so they have some experience in the production of Chinese and Russian bilingual signs.

Dalian area Because Dalian opened up the coast earlier, the styles of sign manufacturers here are a bit different. Some manufacturers are influenced by Japan and South Korea and are more particular about the details and surface treatment (such as polishing and silk screen printing) of acrylic signs. I have seen a small studio in the high-tech zone that specializes in directional signs for high-end shopping malls and office buildings. The polishing of the acrylic edges can achieve a crystal-like effect. Of course, the price has also gone up. The manufacturers in Dalian may be more outstanding in terms of fashion sense and refined craftsmanship.

The pros and cons of choosing local manufacturers

Having dealt with these local manufacturers a lot, I think some of the advantages and disadvantages are quite obvious.

Advantages:

.jpg)

Easy communication : We are both in the Northeast, and share the same language and habits. Face-to-face communication, sample viewing, and modifications are much easier. Especially when urgent orders are made, the local response is often faster.

Better understand local needs : They have a better understanding of the climate environment and installation conditions (such as wall materials and outdoor foundations) in the Northeast, and the suggestions they give are often more down-to-earth. For example, when installing acrylic signs in winter, experienced manufacturers will remind you to allow sufficient curing time for the adhesive, or suggest adding mechanical fixing points.

Flexible support : For small and medium-sized orders or special modification needs, local manufacturers are often more willing to accept them because of their high flexibility. I have encountered cases where a customer wanted to change a few words temporarily. The big southern manufacturers may find it troublesome, but a small local factory can solve the problem with a quick trip.

Shortcomings:

Design capabilities vary : Not all manufacturers have professional design teams, and some are still dominated by "processing thinking." If you need a one-stop process from creative design to production, you have to carefully screen.

Limited process breadth : For some particularly complex processes, such as oversized acrylic one-piece molding and special surface effects (imitation metal etching, interior engraving, etc.), you may still have to find a more specialized factory in the south.

The price may not necessarily be absolutely low : Although long-distance freight is saved, due to factors such as the completeness of the local industrial chain and the scale of raw material procurement, sometimes the unit price may not be lower than purchasing from the south plus freight. A detailed comparison is required.

Some practical suggestions for friends looking for manufacturers

Look at the sample first and then decide : No matter how good the manufacturer's words are, you must look at the actual sample, focusing on the purity of the acrylic plate (whether there are impurities and bubbles), whether the cutting edge is smooth and flat, and the adhesion of silk screen or UV printing. You can ask them to provide samples of different thicknesses and different processes.

Ask about the source of the material : The quality of acrylic sheets varies greatly, and the price and durability of domestic materials, composite materials, and imported materials (such as Germany's Seth and Japan's Mitsubishi) vary significantly. You must ask what kind of material is used, and it is best to indicate the brand or grade in the contract.

Investigate later process details : The temperature difference in the Northeast is large, so you should pay special attention to the manufacturer's treatment of acrylic splicing (whether it is simply glued or reinforced), the fixing method for outdoor installation, and whether it provides suggestions for preventing frost cracking. Responsible manufacturers will consider these.

Don’t just compare prices, compare “comprehensive costs”” : Including the convenience of later maintenance, service life, and the time cost of communication and modification. Sometimes local manufacturers are more expensive, but they can come to you at any time to deal with minor problems, which may save you worry in the long run.

Use local industry circles to inquire : Whether the industrial and commercial circles in the Northeast are big or not, you can often find out which manufacturers have good reputations and are practical by asking colleagues and partners. Going to see their production environment and the cases they are working on is more reliable than just reading brochures.

The number of acrylic sign manufacturers in the Northeast may not be as large as in the South, but there are indeed a group of companies that are doing solid work. They may not be so good at online marketing, and their websites are mediocre, but the masters in the workshops are really good at their jobs. If you are in the Northeast and need to make acrylic signs, you might as well spend some time looking around the local area, and you may be able to find a partner that suits your needs.

This industry is also slowly changing. Some younger generations have begun to take over, introducing new equipment and new concepts. In the future, the service capabilities and creative levels of local manufacturers should continue to improve. After all, having a reliable supplier at their doorstep is always convenient for many companies.

I hope these bits and pieces of sharing can bring you some reference. Market information changes quickly, and what I say may not be comprehensive. The best way is to talk face-to-face with the manufacturer with your specific needs. After all, signs must not only look good, but also be practical. What suits you is the best.